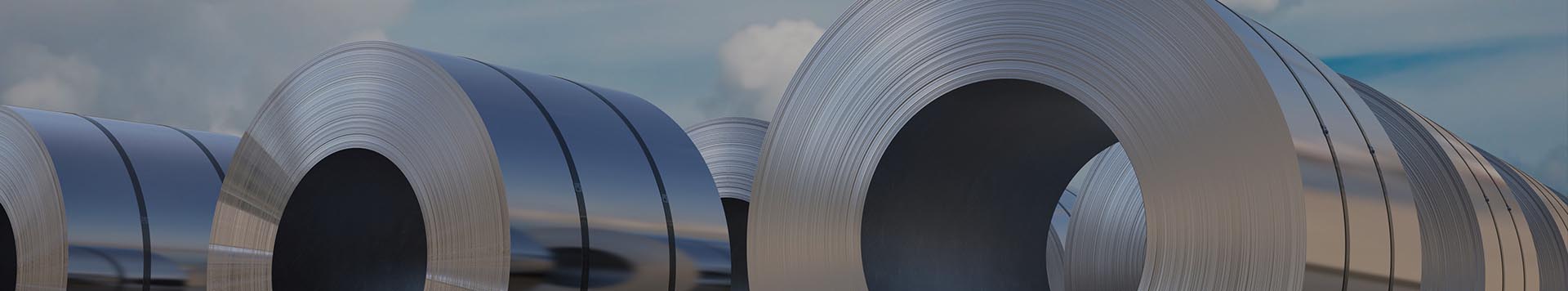

Bakin karfe farantin karfe

Bayanin Samfura

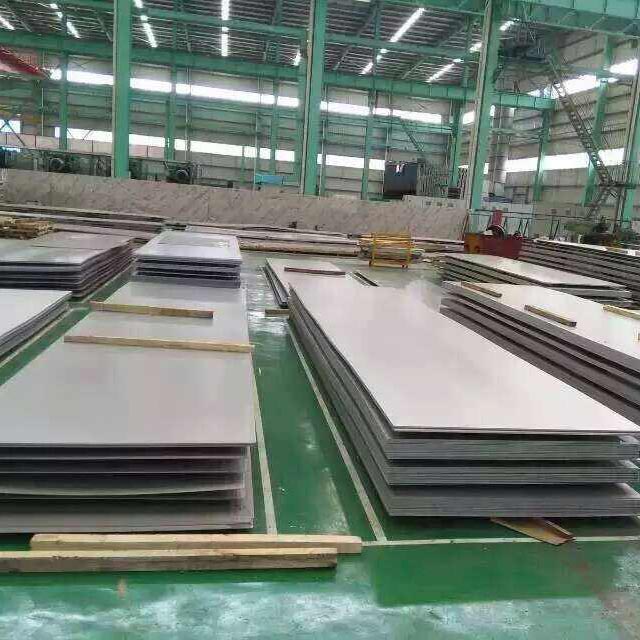

Dangane da hanyar samarwa, akwai nau'ikan birgima mai zafi da mirgina sanyi, gami da takardar kauri 0.5-4 mm da farantin kauri 4.5-35 mm.

Dangane da halaye na tsarin karfe, ana iya raba shi zuwa nau'ikan nau'ikan guda biyar: austenite, austenitic-ferrite, ferrite, martensite da hardening hazo.

Yi amfani da yanayi: ɗaukar lalata na oxalic acid, sulfate-ferric sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfate-copper sulfate, phosphoric acid, formic acid, acetic acid da sauran acid.

Amfani: ana amfani da su a cikin sinadarai, abinci, magunguna, takarda, mai, makamashin atomic da sauran masana'antu, da sassa daban-daban da sassan gine-gine, kayan dafa abinci, kayan tebur, motoci da kayan aikin gida.Domin tabbatar da cewa yawan amfanin ƙasa, ƙarfin ƙarfi, elongation, hardness da sauran kayan aikin injiniya na nau'in nau'i na nau'i na nau'i na nau'i daban-daban sun dace da buƙatun, dole ne a yi amfani da faranti na karfe, maganin warwarewa, maganin tsufa da sauran maganin zafi kafin bayarwa.

Bukatun ingancin: bakin karfe farantin karfe yana da santsi, babban filastik, tauri da ƙarfin injin, kuma yana da tsayayya da lalata acid, alkaline gas, bayani da sauran kafofin watsa labarai.Karfe ne na gami wanda ba shi da sauƙin tsatsa, amma ba shi da cikakkiyar tsatsa.Lalacewar juriya na bakin karfe ya dogara ne akan abun da ke ciki na gami (chromium, nickel, titanium, silicon, aluminum, da dai sauransu) da tsarin ciki.Babban aikin shine chromium.Chromium yana da babban kwanciyar hankali na sinadarai, yana iya samar da fim ɗin wucewa akan saman karfe, keɓe ƙarfe daga waje, kare farantin karfe daga iskar shaka, da haɓaka juriya na farantin karfe.Bayan an lalata fim ɗin wucewa, juriya na lalata zai ragu.

Haɗin Sinadari

| Haɗin kai lambar koyarwa | Alamar | Haɗin sinadarai (ƙaƙƙarfan juzu'i)/% | ||||||||||||||||||||||||||||||||||

| c | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | Sauran | ||||||||||||||||||||||||||

| S30408 | 06Cr19Ni10 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00 ~ 10.50 | 18.00-20.00 | 0.10 | |||||||||||||||||||||||||||

| S30403 | 022Cr19Nil0 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00 ~ 12.00 | 18.00-20.00 | 一 | 一 | 一 | |||||||||||||||||||||||||

| S30409 | 07Cr19Ni10 | 0.04 ~ 0.10 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00 ~ 10.50 | 18.00-20.00 | 一 | |||||||||||||||||||||||||||

| $ 31008 | 06Cr25Ni20 | 0.04 ~ 0.08 | 1.50 | 2.00 | 0.035 | 0.020 | 19.00-22.00 | 24.00 ~ 26.00 | ||||||||||||||||||||||||||||

| S31608 | 06Cr17Ni12Mo2 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00 ~ 3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31603 | 022Cr17Ni12Mo2 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00-3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31668 | 06Cr17Ni12Mo2Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00 ~ 3.00 | 一 | 一 | ≥5C | ||||||||||||||||||||||||

| S39042 | 015Cr21M26Mo5Cu2 | 0.020 | 1.00 | 2.00 | 0.030 | 0.010 | 24,00 ~ 26.00 | 19.00 ~ 21.00 | 4.00 ~ 5.00 | 0.10 | 1.20 ~ 2.00 | 一 | ||||||||||||||||||||||||

| S31708 | 06Cr19Ni13Mo3 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00-20.00 | 3.00 ~ 4.00 | 0.10 | 一 | 一 | ||||||||||||||||||||||||

| S31703 | 022Cr19Ni13Mo3 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00-20.00 | 3.00 ~ 4.00 | 一 | ||||||||||||||||||||||||||

| S32168 | 06Cr18Nil1Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 9.00 ~ 12.00 | 17.0 ~ 19.00 | ≥5C | |||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Haɗin lambar lambar | Alamar | Haɗin sinadarai (ƙaƙƙarfan juzu'i)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | Sauran | ||||||||||||||||||||||||||

| 68 | S21953 | 022Cr19Ni5Mo3S2N | 0.030 | 1.30 ~ 2.00 | 1.00 ~ 2.00 | 0.030 | 0.020 | 18.00 ~ 19.50 | 4.50 ~ 5.50 | 2.50 ~ 3.00 | 一 | 0.05 ~ 0.12 | 一 | |||||||||||||||||||||||

| 70 | S22253 | 022Cr22Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 21.00 ~ 23.00 | 4.50 ~ 6.50 | 2.50 ~ 3.50 | 0.08 ~ 0.20 | 一 | ||||||||||||||||||||||||

| 71 | S22053 | 022Cr23Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 22.00 ~ 23.00 | 4.50 ~ 6.50 | 3.00 ~ 3.50 | 一 | 0.14 ~ 0.20 | 一 | |||||||||||||||||||||||

| Abubuwan sinadaran wasu samfuran a cikin tebur sun bambanta da na GB/T 20878 | ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Haɗin kai lambar koyarwa | Alamar | Haɗin sinadarai (ƙaƙƙarfan juzu'i)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Sauran | |||||||||||||||||||||||||||

| 78 | S11348 | 96C-13A | 0.08 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50 ~ 14.50 | 0.60 | - | - | Al: 0.10 ~ 0.30 | ||||||||||||||||||||||||

| 92 | S11972 | 019Cr19Mo2NbTi | 0.025 | 1.00 | 1.00 | 0.035 | 0.020 | 17.50 ~ 19.50 | 1.00 | 1.75 ~ 2.50 | 0.035 | (Ti+Nb) [0.20+4 (C+N)] ~0.80 | ||||||||||||||||||||||||

| 97 | S11306 | 06Cr13 | 0.06 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50 ~ 13.50 | 0.60 | 一 | 一 | |||||||||||||||||||||||||

| Abubuwan sinadaran wasu samfuran a cikin tebur sun bambanta da na GB/T 20878 | ||||||||||||||||||||||||||||||||||||

Daidaitaccen Kauri

Nisa na bakin karfe farantin:

1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm.

Non-farantin tsawon: 1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm za a iya ƙaddara bisa ga abokin ciniki bukatun.

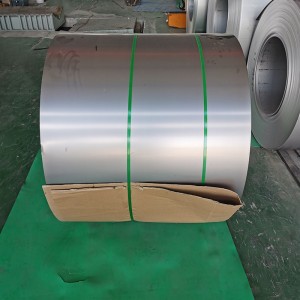

Sashen mirgina sanyi:

Bakin karfe farantin sanyi birgima 2B (nada, tsiri, lebur farantin) halayyar farantin: 3 5mm-6mm 304/2B, 316L/2B.

Kauri: sanyi birgima 2B (0.1-6.0mm).

Surface: 2B santsi surface, BA.

8K madubi;Zane na waya da yashi;Yashi dusar ƙanƙara;Bakin karfe mara sawun yatsa.

Ado panel: launi farantin, titanium farantin, etching farantin, man polishing hairline farantin (HL, NO.4), 3D uku-girma farantin, sandblasting farantin, embossed farantin.

Hot mirgina sashen: bakin karfe farantin zafi mirgina No.1 (nada, lebur farantin).

Kauri: masana'antu No.1 (3-159mm).

Surface: 8K madubi surface;Waya zane, titanium plating, sanding;Yashi dusar ƙanƙara;Bakin karfe mara sawun yatsa.